Offshore Lifeboat Davit Replacement

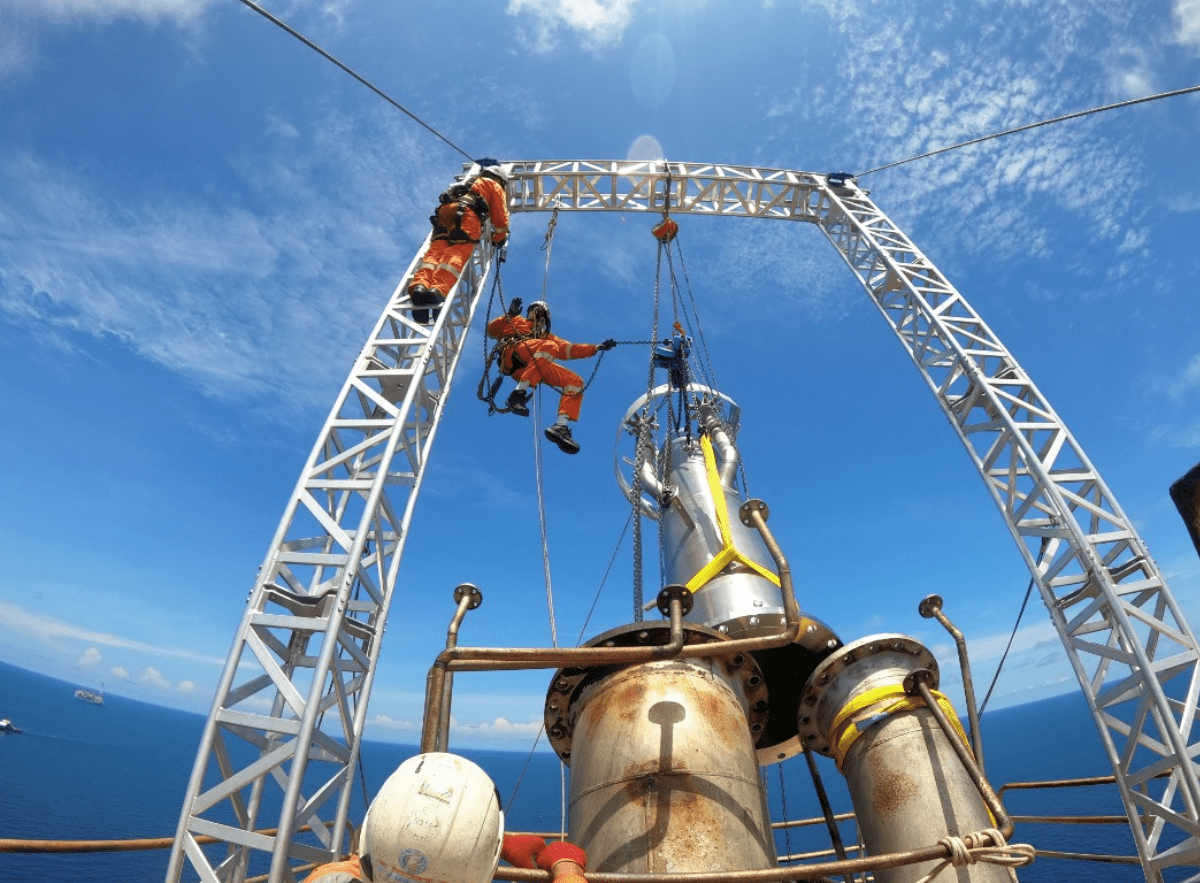

As part of Zenith’s services to the offshore industry, we specialise in the replacement of lifeboat davits on gas and oil platforms. Detailed below gives an overview of a recently completed project that was executed in a safe, cost effective and timely manner:

Zenith was contacted by Shell UK Limited, who operates several offshore platforms in the North Sea, to change out the top vertical section (max 2.5Te lifts) on three of their lifeboat stations and to install new lifeboats. The project presented two key problems:

Firstly, the offshore platform crane could not reach the area where the lifeboat stations were located and secondly, the access to and around the stations proved extremely tight for manoeuvrability of necessary plant, equipment and the newly fabricated vertical sections. The client considered using temporary mobile cranes, additional lifting points and how to utilize scaffolding to allow the crane suitable access, however, this solution would prove onerous due to the load bearing on the platform. An alternative solution had to be found. Zenith proposed the following NINE step solution to the client, which was duly considered and accepted.

STEP 1 – Initial Concept Design

STEP 2 – Full Design Works

STEP 3 – Fabrication and Testing of Equipment

STEP 4 – Project Management of Site Works

STEP 5 – Offshore Pre-Outage Works:

- Mobilise to Offshore Platform and unload equipment and transport to work areas

- Install lifting runway beam and install lifeboat deck level winch

- Install diverter system and associated rigging and install platform temporary support trestles

- Prepare first new platform on weather deck and lift first new platform on to temporary support trestle

- Install fall arrest lines over original first lifeboat and assist with initial stripping of equipment.

STEP 6 – Replace First Lifeboat

STEP 7 – Replace Second Lifeboat

STEP 8 – Replace Third Lifeboat

STEP 9 – Offshore Post-Outage Works