As part of Zenith’s commitment to innovation and excellence through proactive Research and Development, we have recently opened our

‘New Training and Testing Facility’ at our head office in Midlothian. The new facility will prove pivotal as we continue to train and progress the next generation of expertise in the field of specialist access solutions.

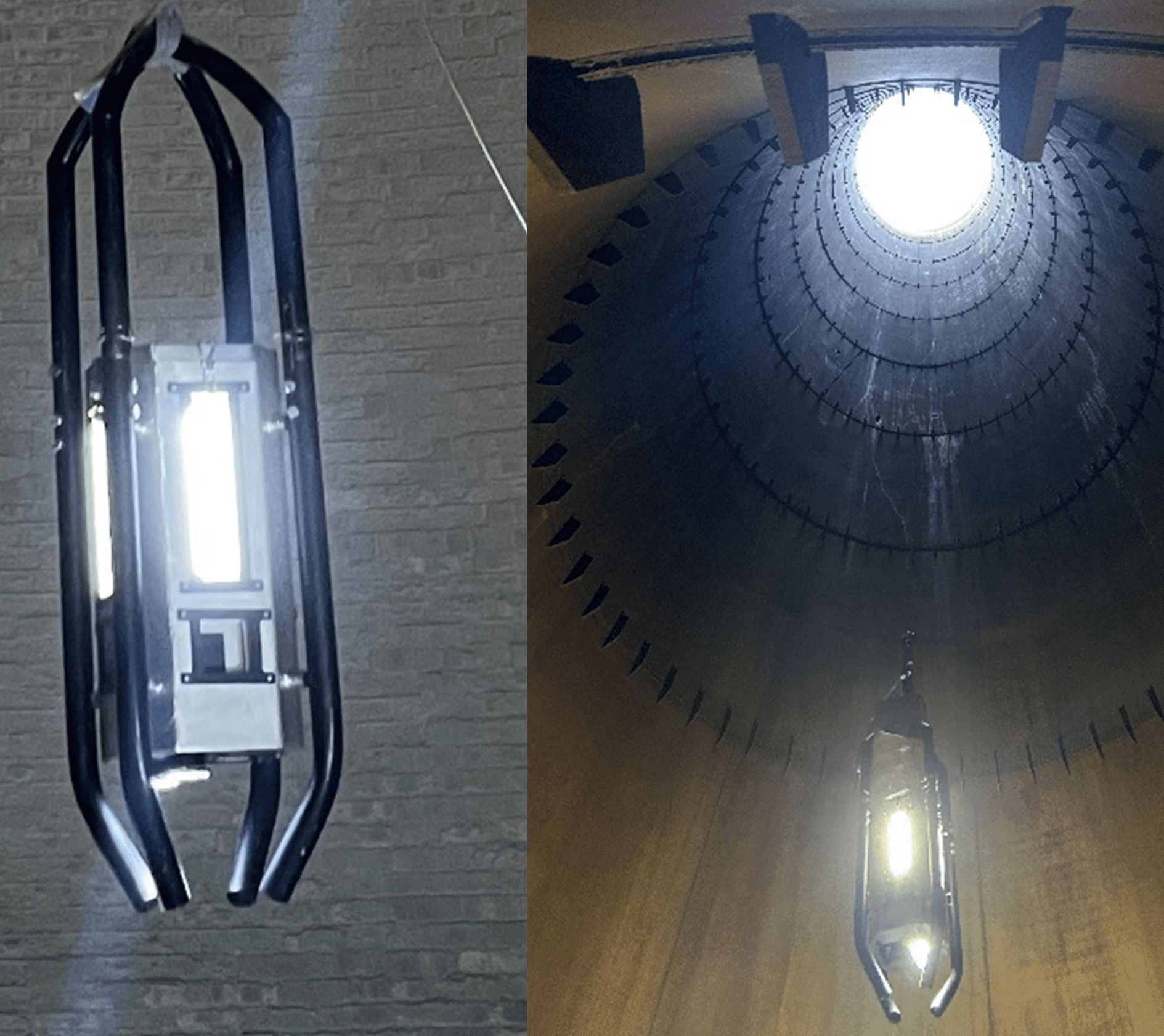

In addition, we will continue to bring innovative specialist access solutions having already successfully brought numerous world-class advancements to keep us at the forefront of the industry. Recent examples of our renowned Research and Development expertise include Zenith’s heavy lifting at height capabilities through the design of our ‘Specialist Lifting Frame’ used to replace flare tips on offshore platforms and FPSO’s around the globe for the world’s leading blue-chip oil and gas companies, Zenith’s industry leading ‘Hot Camera,’ which can inspect the on-line internal linings of industrial chimneys and our pioneering ‘Design & Installation of a Comprehensive Safe Access System’ for distillation towers and similar structures on refineries and petrochemical sites.

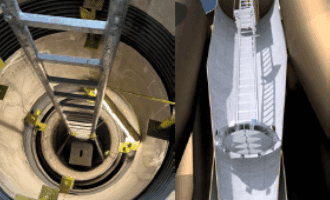

Historically, access to the FCCU was achieved through a combination of traditional scaffolding, rope ladders, and rope access methods, which impacted on the scope of inspections and repairs due to the confined space within the unit and typically the limited time available.

With extensive expertise in providing specialist access solutions and a renowned world class research and development capability, Zenith designed and fabricated a comprehensive range of ‘Specialist Confined Space Access Equipment’ designed to ensure safe installation and operational efficiency throughout the unit.

With Zenith designing, installing and operating the equipment as well as providing a comprehensive rescue capability, our innovative solution for confined space access even allows other specialised contractors to conduct inspection and repair tasks safely. Furthermore,

Zenith offers the expertise and flexibility to design, fabricate, and install customised solutions to tackle even the most challenging confined space access issues. Our world-class specialised confined space access equipment is currently in widespread use across industry sectors, further reinforcing Zenith’s global reputation for innovation and excellence.

Another safe and successful solution includes the design and development of our ‘Innovative Bespoke Access Rope Diverting Device’ for protecting the slate edge roof on buildings, such as recently achieved at the UNESCO World Heritage Site, Edinburgh Castle. Zenith’s ‘New Training and Testing Facility’ is clearly indictive of our progressive approach to training, testing and further Research and Development.